Chimney construction methods and detailed steps?

2023-10-12

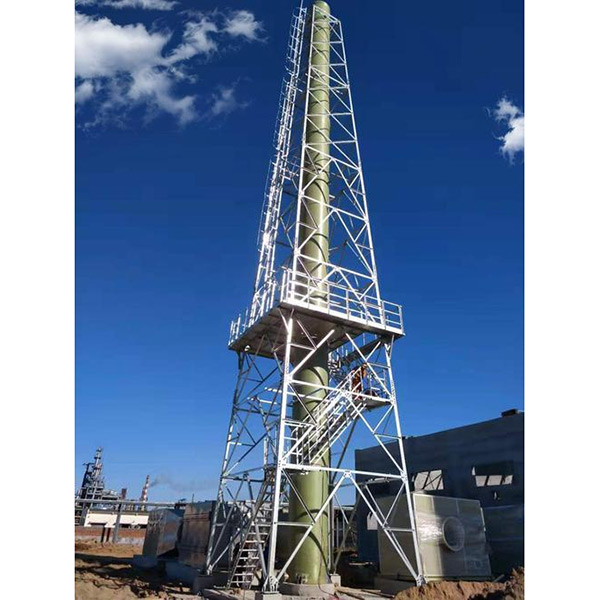

Tower Chimney construction methods and detailed steps?

When it comes to chimneys, everyone must be familiar with it. Chimneys are a very important thing in our lives. From the daily smoke and dust emissions of every household to the waste gas emissions of many factories, chimneys play a very critical role. effect. The installation of the chimney naturally cannot be underestimated. Its installation directly affects the use, but many inexperienced people often do not understand it. Because of IC, this article will introduce the installation of the chimney to provide you with the necessary information. Make a reference when you need it.

Tower Chimney combination installation and construction process

Basic marking → Equipment inventory and inspection → Barrel section assembly and welding → Barrel section acceptance → Barrel wall ladder acceptance → Barrel section installation → Staged acceptance → Overall installation acceptance → Installation completed.

Tower Chimney combination

Combination platform setup

Before the chimney is assembled, a steel-concrete composite platform is set up at a location selected within the crane's lifting radius. According to the on-site space conditions, the platform area should be at least sufficient for the simultaneous assembly of four cylinder sections, and the net distance between the cylinder sections should be greater than 2m to facilitate the ground installation of the chimney platform. In order to facilitate construction workers to enter the inside of the chimney tube section from the bottom, the top elevation of the steel bracket of the combined platform is set to 800mm. A field-shaped platform is set up on the top of the steel bracket based on the diameter of the tube section. The flatness requirement of the top platform is ±1mm. Draw the outer circular outline of the chimney on the horizontal frame of the top platform, weld the limit baffle block on the ribs of the top platform, and prepare the chimney tube section assembly.

Combined hoisting machinery selection

According to the on-site mechanical configuration and project schedule, 7650 crawler crane and 7100 crawler crane were selected. The 7650 crawler crane is mainly responsible for hoisting the cylinder sections into place, and the 7100 crawler crane is responsible for the ground assembly of the cylinder sections. The 7650 crawler crane adopts tower type working condition and is arranged at the rear of the waste heat boiler. It has a main arm of 72m, a auxiliary arm of 36m, a slewing radius of 50m, a rated load of 44.5t, an actual lifting weight of 35t, and a load rate of 78.65%.