How to Choose the Right Channel Support System for Your Project

2025-08-25

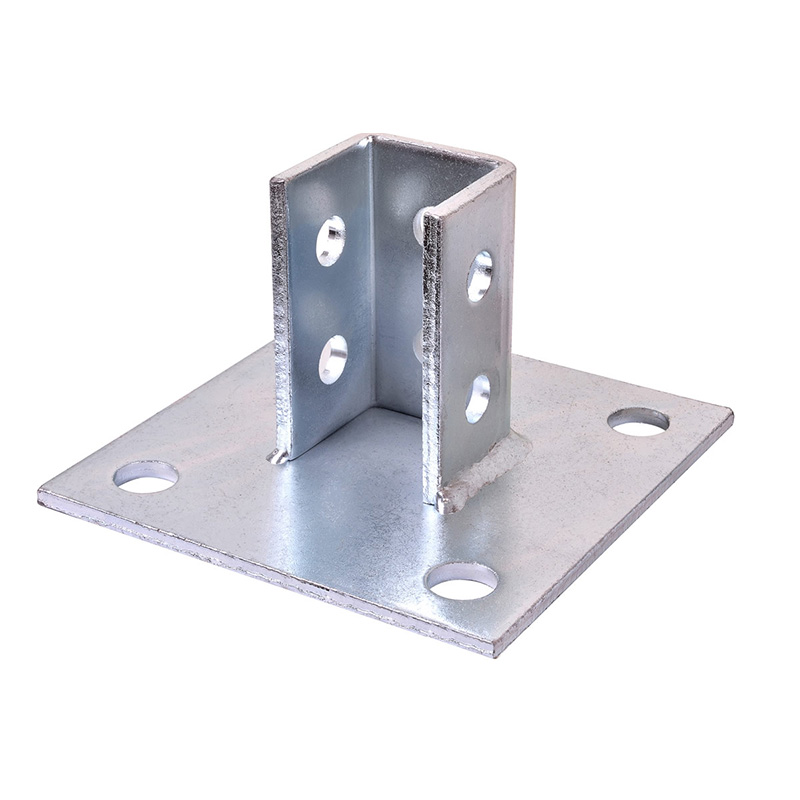

Channel support systems are essential components in construction, mechanical, and industrial projects where pipes, cables, HVAC ducts, and other structural elements require firm support and alignment. These systems consist of steel channels, brackets, fittings, and accessories designed to hold heavy loads securely and distribute weight evenly.

The importance of a robust channel support solution lies in its ability to maintain stability, ensure safety, and optimize installation efficiency. Whether you're working on commercial construction, power plants, or residential buildings, selecting the right type of channel support is crucial to meeting safety standards and improving long-term durability.

Key factors influencing channel support performance:

-

Load-bearing capacity: Determines the maximum weight the system can safely support.

-

Corrosion resistance: Vital for projects in humid or outdoor environments.

-

Material grade: Impacts overall durability and strength.

-

Ease of installation: A well-designed support system reduces labor time and costs.

Product Parameters Overview

| Parameter | Specification |

|---|---|

| Material Options | Stainless Steel, Galvanized Steel, Aluminum |

| Channel Size Range | 41x21mm, 41x41mm, 41x62mm, Custom sizes available |

| Thickness | 1.5mm – 3.0mm |

| Surface Finish | Hot-dip Galvanized, Pre-Galvanized, Powder-Coated |

| Load Capacity | Up to 1500kg per channel depending on model |

| Accessories | Brackets, Nuts, Bolts, Connectors, End Caps |

| Customization | Available upon request |

By analyzing these parameters, engineers and project managers can determine the most suitable channel support system for specific applications, ensuring compliance with both international and local construction standards.

How to Select the Best Channel Support for Different Applications

Choosing the right channel support system depends on project type, environmental conditions, and installation requirements. A mismatch can lead to structural failures, safety hazards, or unnecessary maintenance costs.

Here are the main considerations when selecting a channel support solution:

a) Project Environment

-

Indoor Projects: Standard pre-galvanized steel channels are usually sufficient.

-

Outdoor & Coastal Areas: Hot-dip galvanized or stainless-steel channels provide superior corrosion resistance.

-

Chemical Plants & Food Processing Facilities: Opt for high-grade stainless steel to withstand harsh chemicals and maintain hygiene compliance.

b) Load Requirements

-

Light-Duty: Suitable for small cable trays and lightweight piping.

-

Medium-Duty: Used for supporting HVAC ducts, cable ladders, and medium-sized conduits.

-

Heavy-Duty: Designed for industrial pipelines, electrical risers, and mechanical installations requiring maximum stability.

c) Installation Flexibility

Look for systems offering:

-

Adjustable brackets for varying pipe diameters.

-

Pre-drilled holes for faster assembly.

-

Compatible fittings for quick customization.

By carefully matching environmental needs, load demands, and installation flexibility, you ensure the longevity and reliability of the entire system.

Advantages of Using High-Quality Channel Support Systems

Investing in premium channel support systems benefits both project performance and operational safety. Below are key advantages:

a) Durability and Safety

High-grade materials and anti-corrosion finishes prolong the system's lifespan and reduce maintenance costs. Properly designed supports also prevent accidents caused by falling pipes or loose cables.

b) Cost Efficiency

While initial investment may be higher, a robust channel support system minimizes repair costs, extends component lifespan, and lowers the total cost of ownership.

c) Versatility

Channel supports are suitable for diverse applications:

-

Electrical and plumbing systems

-

HVAC installations

-

Industrial and mechanical projects

-

Renewable energy infrastructure

d) Compliance with International Standards

High-quality supports meet or exceed safety regulations such as ISO 9001 and ASTM standards, ensuring seamless project approvals and inspections.

FAQs About Channel Support Systems

Q1. What is the standard load capacity for channel supports?

A1. The load capacity depends on the channel size, thickness, and material. Standard single-channel configurations typically support between 500kg to 1500kg, while heavy-duty dual-channel arrangements can handle up to 2500kg. Always consult the manufacturer’s load tables for precise specifications.

Q2. How do I ensure corrosion resistance in harsh environments?

A2. Select hot-dip galvanized or stainless steel channels with high anti-corrosion properties. For extreme conditions, such as chemical plants or marine environments, opt for 316-grade stainless steel to ensure long-term reliability and safety.

Choosing the right channel support system is critical for the safety, efficiency, and durability of your infrastructure projects. By understanding load capacities, environmental requirements, and installation flexibility, you can make informed decisions that save both time and costs.

At GRANDIND, we specialize in delivering high-quality channel support systems tailored to your unique project needs. Our products are engineered to meet international standards and optimized for both small-scale and large-scale applications.

If you’re looking for a reliable partner to supply top-performing channel support systems, contact us today to discuss your requirements and receive expert assistance.