How Do Multi-Mode Laser Diodes Improve Optical Performance?

2025-08-26

In the rapidly evolving field of optoelectronics, multi-mode laser diodes are becoming indispensable for applications that require high optical power, wide beam profiles, and enhanced energy efficiency. Whether in fiber optics, material processing, medical diagnostics, or 3D sensing, these diodes offer a combination of power, reliability, and versatility that makes them a leading choice for engineers and researchers alike.

What Are Multi-Mode Laser Diodes and How Do They Work?

A multi-mode laser diode (MMLD) is a semiconductor-based light source that emits multiple transverse optical modes simultaneously. Unlike single-mode laser diodes that generate a narrow, highly coherent beam, multi-mode variants deliver higher optical power output at the expense of beam divergence.

These diodes are built using compound semiconductors like GaAs, InP, or GaN, depending on the desired wavelength. Their core structure consists of:

-

Active region – where electron-hole recombination produces photons.

-

Waveguide layer – guides the photons while allowing multiple transverse modes to propagate.

-

Cladding layer – confines the light within the waveguide and improves efficiency.

Working Principle

When a forward voltage is applied to the laser diode, electrons and holes recombine in the active region, producing photons. In a multi-mode configuration, the waveguide is wider, enabling multiple transverse modes to coexist. This structural difference results in:

-

Higher power density

-

Wider emission angles

-

Slightly reduced beam quality compared to single-mode diodes

Key Features and Specifications of Multi-Mode Laser Diodes

When selecting a multi-mode laser diode, technical specifications play a decisive role. Below are the essential parameters that define the performance of these devices:

| Parameter | Description | Typical Range |

|---|---|---|

| Wavelength | Central emission wavelength of the diode | 405 nm – 1550 nm |

| Optical Output Power | Maximum continuous-wave power output | 50 mW – 10 W |

| Operating Current | Electrical current required for stable lasing | 100 mA – 2 A |

| Threshold Current | Minimum current needed to initiate lasing | 20 mA – 200 mA |

| Beam Divergence | Angular spread of emitted light | 5° – 40° (typical) |

| Spectral Width | Wavelength spread of emitted light | 1 nm – 5 nm |

| Operating Temperature | Safe working range for diode operation | -20°C to +85°C |

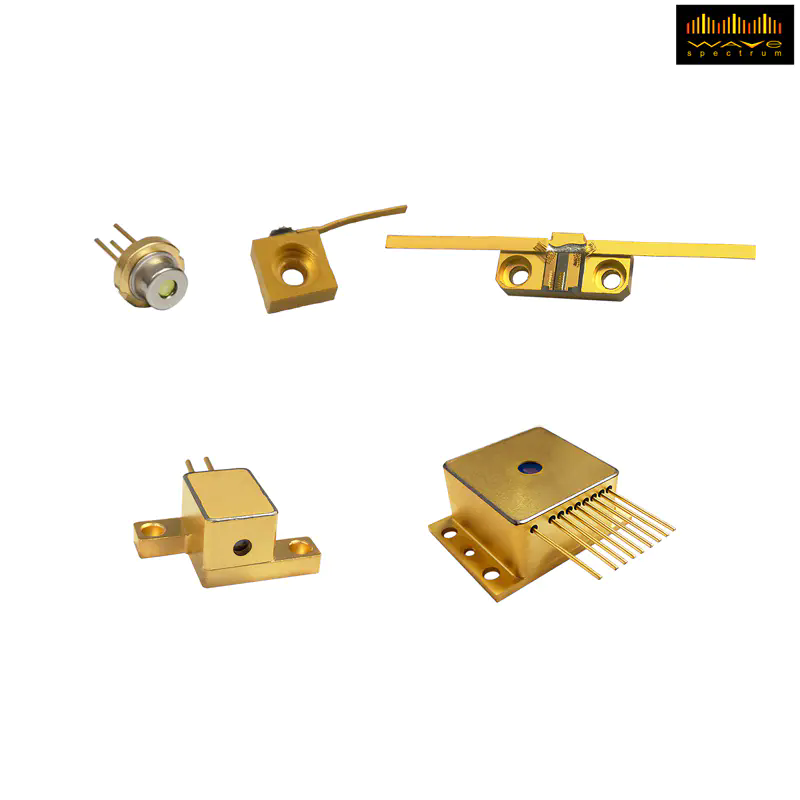

| Package Types | Encapsulation formats to match different applications | TO-Can, C-Mount, Fiber-Coupled |

Advantages of Multi-Mode Laser Diodes

-

High Optical Power – Ideal for demanding applications like cutting, welding, or illumination.

-

Robust Performance – Better tolerance to misalignment and thermal variations.

-

Wavelength Variety – Available in visible, near-infrared, and mid-infrared ranges.

-

Cost-Effectiveness – Lower manufacturing costs compared to single-mode lasers for high-power outputs.

Applications Across Industries

Multi-mode laser diodes are widely used in multiple sectors due to their power efficiency, compact size, and versatility. Here are some of the major application areas:

a) Fiber-Optic Communications

While single-mode lasers dominate long-distance data transmission, multi-mode diodes are ideal for short-reach optical networks and LAN interconnections due to their high power and ease of coupling with multimode fibers.

b) Material Processing

Industries use multi-mode laser diodes for:

-

Precision cutting and engraving

-

Plastic welding

-

Additive manufacturing (3D printing)

Their high-power density and adjustable beam profiles make them suitable for automated industrial workflows.

c) Medical Diagnostics & Therapy

Medical systems rely on multi-mode laser diodes for:

-

Non-invasive imaging

-

Photodynamic therapy

-

Surgical illumination

-

Blood analysis devices

d) Automotive and Consumer Electronics

In the automotive industry, multi-mode diodes power LiDAR sensors, head-up displays, and driver-assist systems. For consumer electronics, they are integral to laser projectors, optical storage systems, and gesture recognition devices.

e) Defense and Security

Military and security systems utilize multi-mode laser diodes for:

-

Laser range finding

-

Target designation

-

Infrared countermeasures

Buying Guide and Integration Considerations

Choosing the right multi-mode laser diode depends on aligning its technical specifications with your application requirements. Here are some professional considerations:

a) Wavelength Selection

Match the emission wavelength with your target medium:

-

405 nm – 450 nm → Blu-ray systems and biomedical imaging

-

808 nm – 980 nm → Pump lasers and material processing

-

1310 nm – 1550 nm → Fiber-optic communications

b) Optical Power Requirements

Ensure the output power supports your operational demands. Overpowering can lead to thermal stress and shortened lifespan, while underpowering can cause system inefficiencies.

c) Thermal Management

Since multi-mode diodes generate significant heat, effective cooling strategies like thermoelectric coolers (TEC) or heatsinks are critical for maintaining performance and extending lifespan.

d) Packaging Format

Select from TO-Can, C-Mount, Butterfly, or Fiber-Coupled packages based on mechanical integration needs.

e) Drive Circuitry

Stable drive current is vital to ensure consistent optical power output and avoid catastrophic optical damage (COD). Choose current-regulated drivers with integrated protection mechanisms.

Multi-Mode Laser Diode FAQs

Q1: What are the key differences between single-mode and multi-mode laser diodes?

A: Single-mode diodes produce a highly coherent, narrow beam ideal for precision optical communication and long-distance applications. Multi-mode diodes, on the other hand, emit higher optical power with a wider beam divergence, making them more suitable for short-range, high-power, or illumination-based applications.

Q2: How can I extend the lifespan of a multi-mode laser diode?

A: To maximize lifespan, ensure proper thermal management, avoid current overshoot, and operate within the recommended temperature and current ratings. Using a high-quality driver circuit and implementing protective measures such as ESD shielding will also enhance longevity.

Multi-mode laser diodes represent a critical technology in modern optoelectronic systems, combining high optical power, broad wavelength options, and cost-effective integration for industrial, medical, communication, and consumer applications.

At WAVESPECTRUM, we specialize in delivering high-performance multi-mode laser diodes that meet rigorous quality standards and are optimized for diverse application environments. Our products offer superior reliability, excellent thermal stability, and a wide selection of package formats tailored to your needs.

For inquiries, bulk orders, or custom solutions, contact us today to discuss how WAVESPECTRUM can support your optical innovation.